The Indian government has launched the Green Steel Mission, a transformative ₹15,000 crore initiatives aimed at decarbonizing the steel industry. This initiative is a crucial step toward India’s commitment to achieving net-zero emissions by 2070. The mission underscores the importance of the steel sector in fostering environmental sustainability, aiming not only to reduce the sector's carbon footprint but also to contribute to India’s broader climate goals.

The Steel Sector in India:

Production

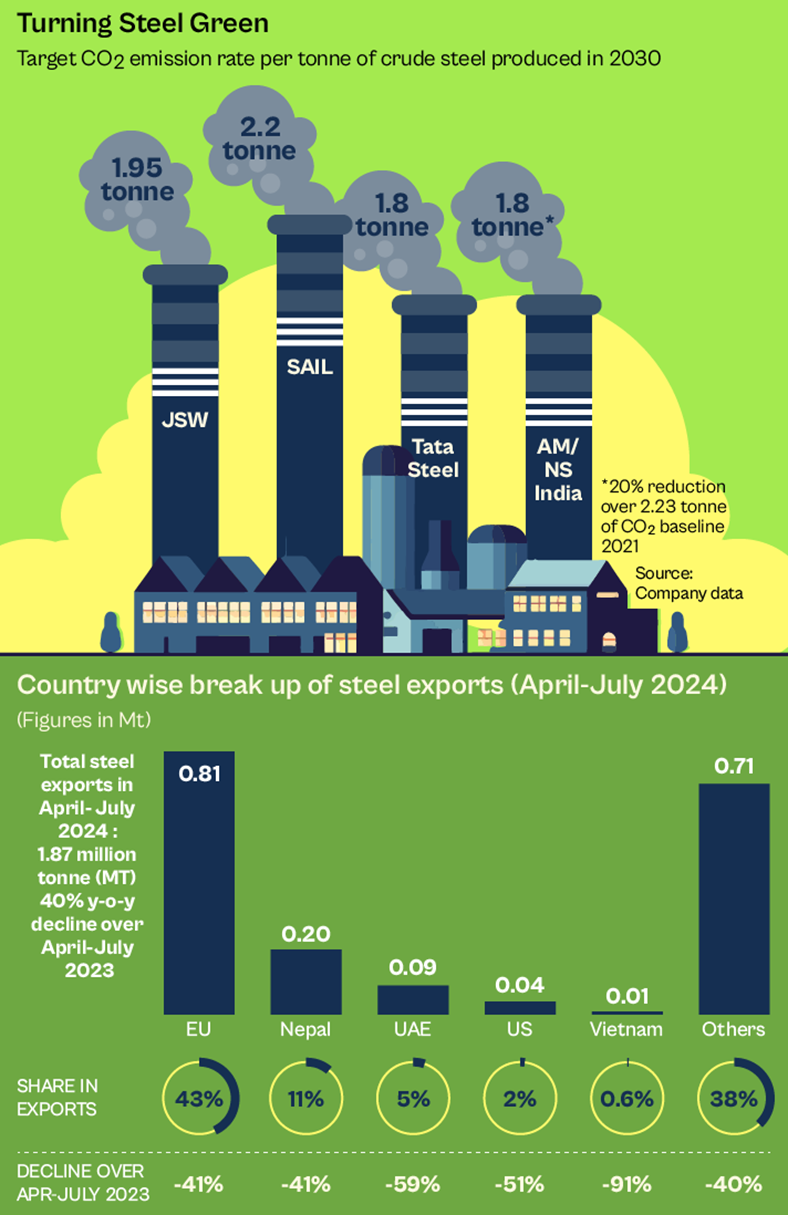

India’s crude steel capacity reached 179.5 million tonnes in 2023-24, with consistent growth in the production of finished steel, including alloy and non-alloy varieties. In the same period, India produced 139.15 million tonnes of finished steel. The private sector plays a dominant role in the industry, contributing around 83% of the total crude steel output. The National Steel Policy 2017 sets ambitious targets for the steel sector, aiming for a production capacity of 300 million tonnes by 2030-31, positioning India to become a global leader in steel production.

Consumption

From April to October 2024, finished steel consumption in India reached approximately 75.6 million tonnes, with per capita steel consumption standing at 86.7 kilograms in FY23. These figures indicate steady domestic demand for steel, which is vital for infrastructure development, industrial growth, and overall economic progress.

Green Steel Mission: Overview

The Green Steel Mission is designed to decarbonize the steel sector, with a focus on reducing its carbon footprint through innovative technologies and strategies. The key components of the mission include:

1. Production-Linked Incentive (PLI) Scheme for Green Steel: This scheme incentivizes the production of green steel, aiming to attract investments and increase domestic manufacturing, especially in specialty steel. The scheme will help reduce reliance on steel imports and boost India’s self-sufficiency in steel production.

2. Incentives for Renewable Energy: The mission promotes the use of renewable energy sources—such as solar, wind, and hydrogen—during steel production. By shifting to cleaner energy, the steel sector can significantly reduce its carbon emissions and contribute to the country's renewable energy goals.

3. Mandates for Government Agencies: The government has introduced policies requiring government agencies to purchase green steel, creating a guaranteed demand and further supporting the growth of sustainable practices in the industry.

Benefits of Decarbonizing the Steel Industry:

· Global Climate Impact: The decarbonization of the steel sector will contribute significantly to global climate goals by reducing emissions. This effort will aid in meeting Paris Agreement targets, helping limit the global temperature rise and promoting environmental sustainability worldwide.

· Health and Environmental Protection: By adopting cleaner technologies and sustainable practices, the steel sector will reduce pollution levels, improving air and water quality and mitigating adverse health impacts on local communities. It will also help prevent environmental degradation, protecting natural resources for future generations.

· Job Creation: The shift to green steel will generate new employment opportunities across various sectors, including renewable energy, technology development, and infrastructure, fostering economic growth and stability in affected regions.

Related Policies and Initiatives:

· Task Forces: To drive the decarbonization agenda, the Ministry of Steel has formed 14 task forces comprising industry experts, academic institutions, think tanks, and government bodies. These task forces have contributed to the development of a report titled ‘Greening the Steel Sector in India: Roadmap and Action Plan’, which was released in September 2024, outlining a detailed approach for decarbonizing the steel sector.

· Steel Scrap Recycling Policy (2019): This policy promotes the domestic availability of scrap, supporting a circular economy. It facilitates the establishment of metal scrapping centers for recycling ferrous scrap, including End-of-Life Vehicles (ELVs), ensuring that valuable materials are reused within the country.

· Vehicle Scrapping Policy (2021): This policy aims to increase the availability of scrap for the steel sector by implementing strict rules under the Motor Vehicles Act, encouraging the scrapping of old vehicles and thus generating more steel scrap for recycling.

· National Solar Mission (2010): This mission encourages the use of solar energy across various sectors, including steel production, thus contributing to emission reductions and further supporting green steel initiatives.

· Perform, Achieve, and Trade (PAT) Scheme: The PAT scheme incentivizes steel manufacturers to improve energy efficiency, reducing their carbon footprint and energy consumption, contributing to the sector’s overall decarbonization.

· National Green Hydrogen Mission: With an allocated budget of ₹455 crore, this mission aims to implement pilot projects in the steel sector, such as producing Direct Reduced Iron (DRI) using 100% hydrogen. This will help reduce coal and coke consumption in blast furnaces, supporting the decarbonization of steel production.

· Green Steel Taxonomy: Introduced in December 2024, the Green Steel Taxonomy defines and categorizes low-emission steel, creating a market for green steel and providing financial support for green initiatives.

· Carbon Credit Trading Scheme (CCTS): Launched in June 2023, the CCTS allows sectors like steel to trade carbon credits, incentivizing emissions reductions and promoting sustainable practices across industries.

Specialty Steel and PLI Scheme:

The PLI scheme for specialty steel is a key part of India’s strategy to enhance its steel sector. This scheme is designed to attract capital investment and reduce imports. Companies participating in the scheme have committed an investment of ₹27,106 crore, generating 14,760 direct jobs and contributing 7.90 million tonnes of specialty steel production. As of October 2024, ₹17,581 crore had been invested, resulting in the creation of over 8,660 jobs.

Capacity Expansion and Raw Material Security

India remains largely self-sufficient in steel production, with imports accounting for a small percentage. To further support the sector:

1. Reduction in Basic Customs Duty (BCD): The government reduced the BCD on Ferro Nickel from 2.5% to zero, and extended the duty exemption on ferrous scrap until March 2026, encouraging domestic production.

2. Safety Guidelines: In July 2024, the Ministry of Steel released sixteen new safety guidelines for the iron and steel sector, improving workplace safety and productivity.

3. Steel Import Monitoring System (SIMS) 2.0: The revamped SIMS system provides detailed information on imported steel standards and grades, enabling better policy decisions and improving the monitoring of steel imports.

The government is also working on ensuring raw material security, with a focus on high-quality coking coal imports. To diversify sourcing, India is exploring partnerships with countries such as Australia, the U.S., Russia, Indonesia, and Mozambique, as well as Mongolia.

Ensuring Quality through Standardization

To maintain high standards in steel production, the government has implemented standardization measures through Quality Control Orders (QCOs). The Bureau of Indian Standards (BIS) has formulated 151 steel standards to ensure that Indian steel meets international quality norms. Additionally, the merged SIMS 2.0 and TCQCO portal facilitates seamless integration with the customs ICEGATE system, improving the efficiency of steel imports and exports.

Conclusion and Way Forward:

Decarbonizing the steel industry is crucial for combating climate change and ensuring sustainable growth. By adopting energy efficiency measures, renewable energy, green hydrogen, and carbon capture technologies; India’s steel sector can significantly reduce its carbon footprint. The collaboration of the government, industry stakeholders, and research organizations will be essential to accelerate the transition. The Green Steel Mission represents a transformative step toward a greener and more sustainable future for India’s steel industry, aligning economic growth with environmental stewardship.

| Main question: The steel industry is a major emitter of carbon. How can the integration of renewable energy and green hydrogen in the sector contribute to decarbonization? Critically evaluate the potential challenges and benefits associated with this transition. |